There are six critical inputs needed to size any expansion tank:

1. Amount of fluid to be heated

2. The type of fluid being heated

3. The starting temperature of the fluid

4. The ending temperature of the fluid

5. The minimum or starting pressure of the fluid

6. The maximum or ending pressure of the fluid

First, let’s define each one of these components. Amount of fluid is the gallons of system volume. This can be obtained either from the system drawings or estimated based on the size of the trunk main of the system and the dimensions of the building. Often, an accurate way to acquire this number is to ask a chemical treatment professional. They can dilute a trace chemical in the system and then measure that dilution, which can be used to extrapolate the system size.

The type of fluid being heated is normally water or a mix of glycol and water. The specific volume of glycol increases with temperature faster than that of water. The difference between the specific volume at the starting and ending temperatures dictates the percentage increase in volume of the fluid. It should be noted that the piping system will also increase in size as it is heated. ASHRAE sizing, and most manufacturers, use a net expansion factor that accounts for the change in specific volumes less the expansion of the piping.

The type of fluid being heated is normally water or a mix of glycol and water. The specific volume of glycol increases with temperature faster than that of water. The difference between the specific volume at the starting and ending temperatures dictates the percentage increase in volume of the fluid. It should be noted that the piping system will also increase in size as it is heated. ASHRAE sizing, and most manufacturers, use a net expansion factor that accounts for the change in specific volumes less the expansion of the piping.

The starting and ending temperatures of the fluid depend on the type of system. For a heating system, the starting temperature is normally ambient, or 70 degrees Fahrenheit. The final temperature is typically your operating temperature, equal to the boiler set point. For a chilled water system, the starting temperature is normally the operating temperature or 30 to 40 degrees Fahrenheit. The final temperature of the chilled water system occurs if the system is allowed to go from operating temperature to ambient. The temperature used for tank sizing is typically 100 degrees Fahrenheit, which is the temperature of a very hot day for most areas.

The minimum starting pressure for the tank depends on the height of the building above the expansion tank location. Starting with a penthouse installation, the pressure of the piping in the top floor installation needs to be 10 psi to ensure proper purging of the air that can collect at high points in the system. This means that the expansion tank located in a penthouse would be set for that same pressure, or 10 psi. As the tank moves downward in the system, an increase of 1 psi is needed for every 2.3 feet from the top. If the tank moves down 80 feet from the top, an additional 80 feet/2.3 feet per psi, or 35 psi more is added. The resulting charge for the tank is 35 psi plus 10 psi (needed at the top) or 45 psi.

The minimum starting pressure for the tank depends on the height of the building above the expansion tank location. Starting with a penthouse installation, the pressure of the piping in the top floor installation needs to be 10 psi to ensure proper purging of the air that can collect at high points in the system. This means that the expansion tank located in a penthouse would be set for that same pressure, or 10 psi. As the tank moves downward in the system, an increase of 1 psi is needed for every 2.3 feet from the top. If the tank moves down 80 feet from the top, an additional 80 feet/2.3 feet per psi, or 35 psi more is added. The resulting charge for the tank is 35 psi plus 10 psi (needed at the top) or 45 psi.

The maximum ending pressure is normally set by the “weakest link” of the system. For example, if a boiler, heat exchanger, and air handler have maximum pressures of 100, 150, and 75 psi, respectively, you may be tempted to think the air handler is that “weakest link”. If, however, the air handler is at the top of the piping system, the pressure of a 65 psi increase from 10 psi to 75 psi is allowable. The boiler, if located at ground level where the pressure is 45 PSI to start, can only experience a 55 psi increase before it reaches its maximum rated pressure. A good practice is to allow the maximum pressure to increase by 25 to 35 psi over the initial starting pressure. Consider an operator watching the cycle of the HVAC system; if they observe an increase from 45 psi to 100 psi, they may consider that an abnormally high-pressure swing. Observing a pressure from 45 to 70 PSI is deemed in the eye of most operators as normal, as it does not approach the equipment’s maximum pressure.

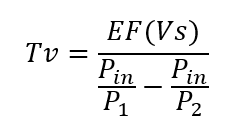

The governing equation for sizing any expansion tank is:

Tv=(EF(Vs))/(Pin/P1 -Pin/P2)

Where:

Tv = Tank volume

EF = expansion factor of fluid

Vs = System Volume

Pin = initial or pre-charge pressure (psia)

P1 = starting pressure for system (psia=psig+14.7)

P2 = final pressure for system (psia=psig+14.7)

EF is the expansion factor that equals the percentage difference of the starting and ending specific volume of the fluid, minus the volumetric expansion of the system piping. Expansion factor tables are available from most manufacturers to make this calculation more convenient.

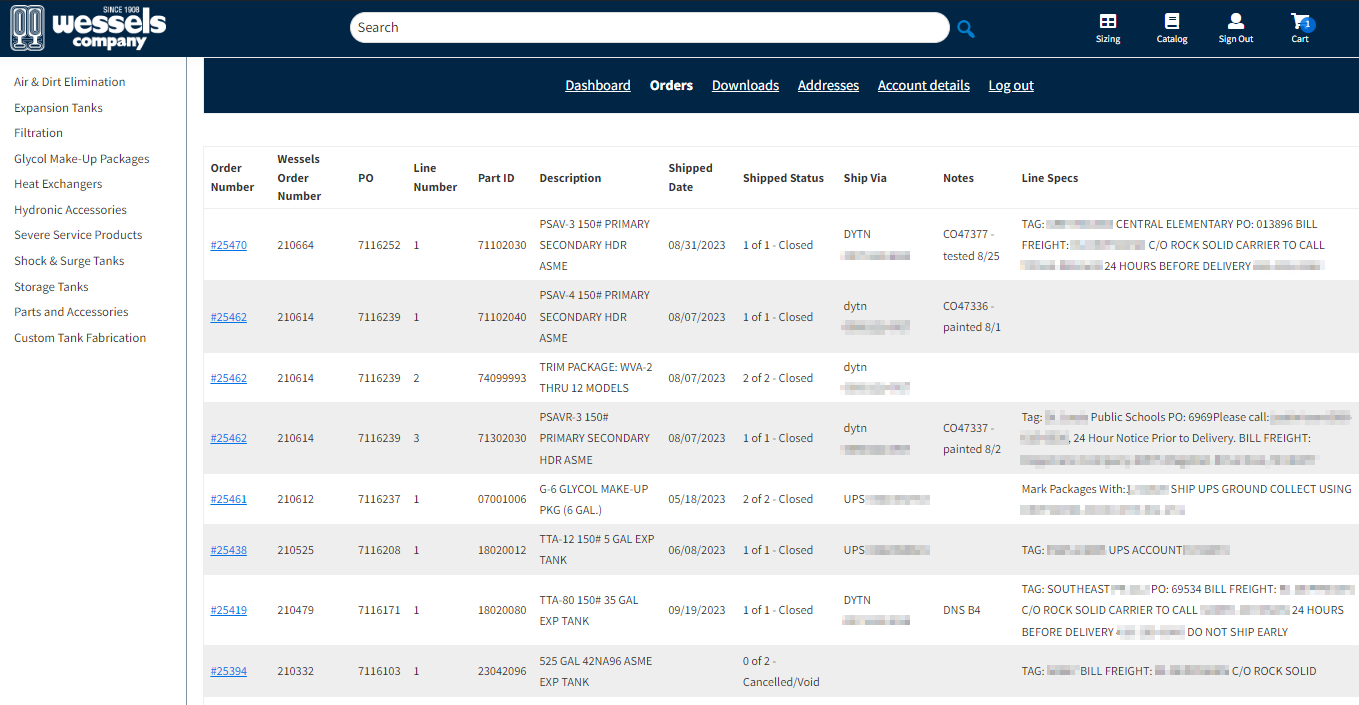

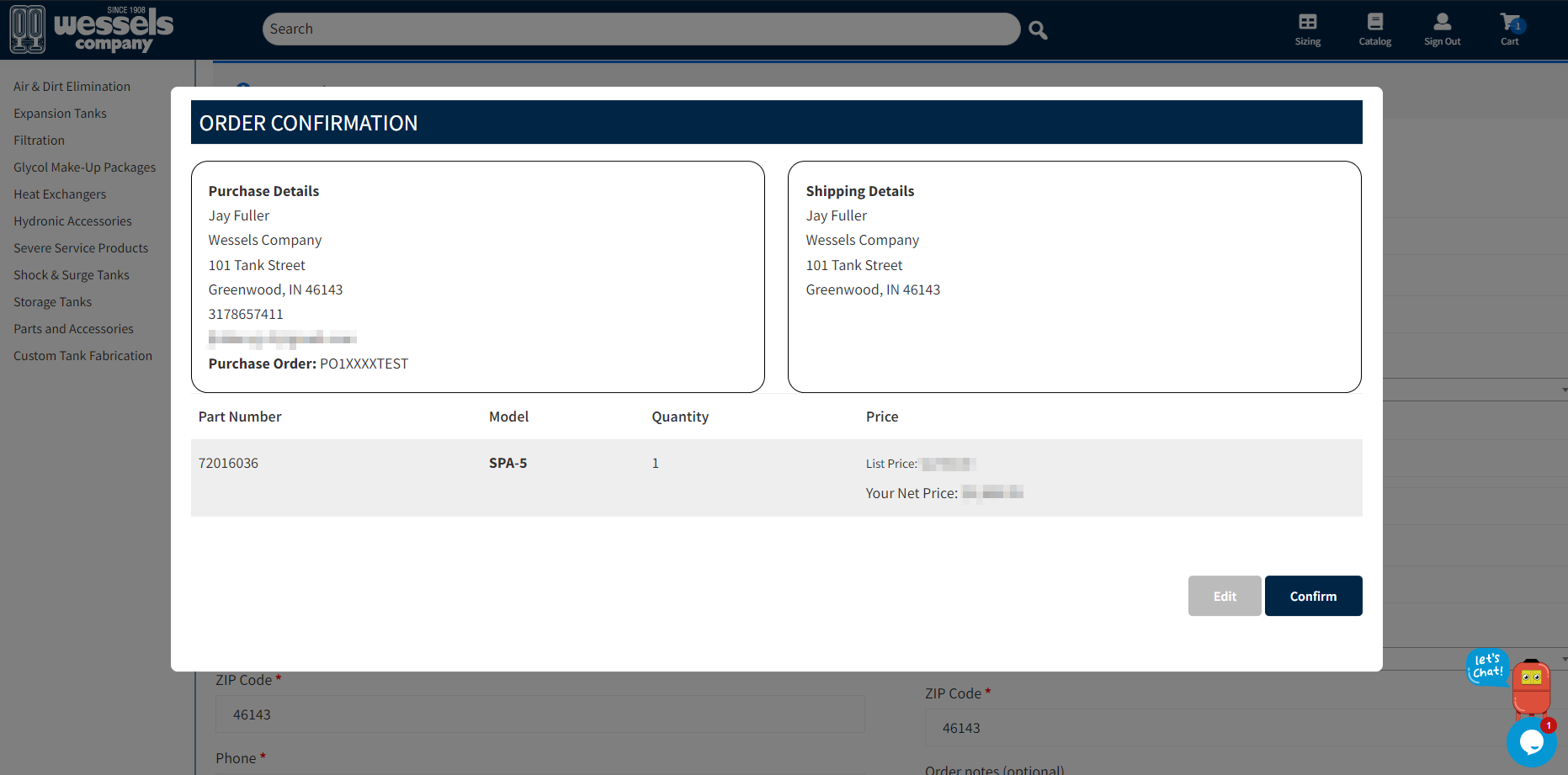

Once you know the tank volume (Tv) you need, you can cross-reference that number with the acceptance volume of expansion tanks in our PDF catalog or our online ordering catalog wesselsvessels.com

You can also download the Wessels Company phone apps or use you web-browser to access free-to-use sizing software by clicking “Size Your Tank Now”

More →

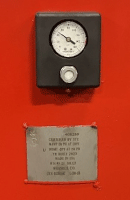

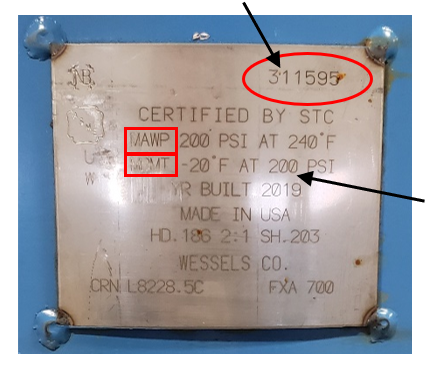

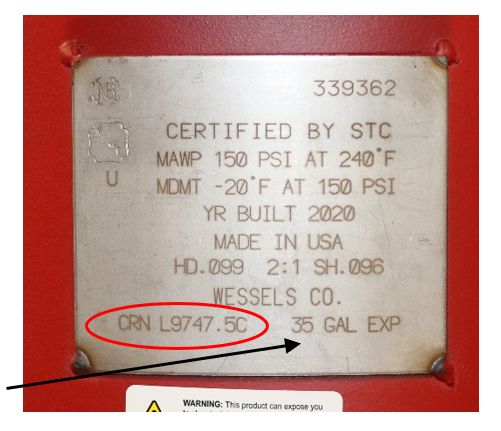

Every pressure vessel manufactured by Wessels Company is equipped with a metal data tag affixed to its front side, positioned below the smart bracket system. This data tag serves as a quick reference for essential vessel information.

Every pressure vessel manufactured by Wessels Company is equipped with a metal data tag affixed to its front side, positioned below the smart bracket system. This data tag serves as a quick reference for essential vessel information.

Additionally, the tag includes the manufacturing year, affirming its origin in the United States. H.D. denotes Head Dimension, indicating the size of the vessel’s top, while SH signifies the shell thickness or steel gauge employed in its construction.

Additionally, the tag includes the manufacturing year, affirming its origin in the United States. H.D. denotes Head Dimension, indicating the size of the vessel’s top, while SH signifies the shell thickness or steel gauge employed in its construction.

GREENWOOD, IND. – Wessels Company is thrilled to announce the debut of its latest product enhancements at the AHR Expo in Chicago, showcased at booth 6321. Among the highlights is the new Drum Mounted Glycol Makeup Package, known as DM-GMP, featuring enhanced mobility and refill capabilities. The system ingeniously mounts atop a standard drum containing glycol or glycol mixture, streamlining the refill and installation process.

GREENWOOD, IND. – Wessels Company is thrilled to announce the debut of its latest product enhancements at the AHR Expo in Chicago, showcased at booth 6321. Among the highlights is the new Drum Mounted Glycol Makeup Package, known as DM-GMP, featuring enhanced mobility and refill capabilities. The system ingeniously mounts atop a standard drum containing glycol or glycol mixture, streamlining the refill and installation process. In addition to these advancements, the industry-leading smart bracket technology has undergone a redesign to be more compact and resilient. The WessView® bladder monitor, air pressure gauge, and Schrader valve have all been optimized to snugly fit the exterior of the tank with a single connection. The ASME tank and smart system seamlessly integrate all essential technologies into a convenient location. The new smart bracket will become a standard feature on all bladder-style tanks later this year.

In addition to these advancements, the industry-leading smart bracket technology has undergone a redesign to be more compact and resilient. The WessView® bladder monitor, air pressure gauge, and Schrader valve have all been optimized to snugly fit the exterior of the tank with a single connection. The ASME tank and smart system seamlessly integrate all essential technologies into a convenient location. The new smart bracket will become a standard feature on all bladder-style tanks later this year.

We happily introduce the newest smiling face to the Wessels family, Allyson McQueen! She joined our engineering department at the beginning of November as a Process Engineer. She loves learning new things, which will surely benefit her in her new role on our engineering team. Allyson is an avid sports fan and has many teams she roots for including the Florida Gators, Atlanta Braves, Miami Dolphins, and the L.A. Lakers. She is a dog lover and has a large German Shepherd who she loves to spoil. In her free time, she can be found training large dogs and playing darts around the country in tournaments.

We happily introduce the newest smiling face to the Wessels family, Allyson McQueen! She joined our engineering department at the beginning of November as a Process Engineer. She loves learning new things, which will surely benefit her in her new role on our engineering team. Allyson is an avid sports fan and has many teams she roots for including the Florida Gators, Atlanta Braves, Miami Dolphins, and the L.A. Lakers. She is a dog lover and has a large German Shepherd who she loves to spoil. In her free time, she can be found training large dogs and playing darts around the country in tournaments.

The type of fluid being heated is normally water or a mix of glycol and water. The specific volume of glycol increases with temperature faster than that of water. The difference between the specific volume at the starting and ending temperatures dictates the percentage increase in volume of the fluid. It should be noted that the piping system will also increase in size as it is heated. ASHRAE sizing, and most manufacturers, use a net expansion factor that accounts for the change in specific volumes less the expansion of the piping.

The type of fluid being heated is normally water or a mix of glycol and water. The specific volume of glycol increases with temperature faster than that of water. The difference between the specific volume at the starting and ending temperatures dictates the percentage increase in volume of the fluid. It should be noted that the piping system will also increase in size as it is heated. ASHRAE sizing, and most manufacturers, use a net expansion factor that accounts for the change in specific volumes less the expansion of the piping. The minimum starting pressure for the tank depends on the height of the building above the expansion tank location. Starting with a penthouse installation, the pressure of the piping in the top floor installation needs to be 10 psi to ensure proper purging of the air that can collect at high points in the system. This means that the expansion tank located in a penthouse would be set for that same pressure, or 10 psi. As the tank moves downward in the system, an increase of 1 psi is needed for every 2.3 feet from the top. If the tank moves down 80 feet from the top, an additional 80 feet/2.3 feet per psi, or 35 psi more is added. The resulting charge for the tank is 35 psi plus 10 psi (needed at the top) or 45 psi.

The minimum starting pressure for the tank depends on the height of the building above the expansion tank location. Starting with a penthouse installation, the pressure of the piping in the top floor installation needs to be 10 psi to ensure proper purging of the air that can collect at high points in the system. This means that the expansion tank located in a penthouse would be set for that same pressure, or 10 psi. As the tank moves downward in the system, an increase of 1 psi is needed for every 2.3 feet from the top. If the tank moves down 80 feet from the top, an additional 80 feet/2.3 feet per psi, or 35 psi more is added. The resulting charge for the tank is 35 psi plus 10 psi (needed at the top) or 45 psi.