Seeing Green with Water-Side Economizing and Free Cooling

Happy Earth Day! New requirements to repair and upgrade existing buildings and infrastructure in an effort to lower emissions and improve energy efficiency means greener energy for the planet and an opportunity to see green as HVAC equipment providers.

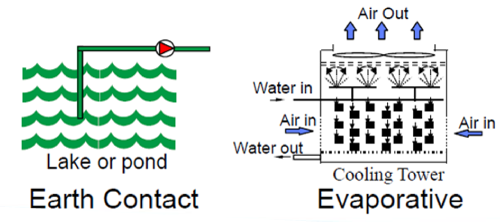

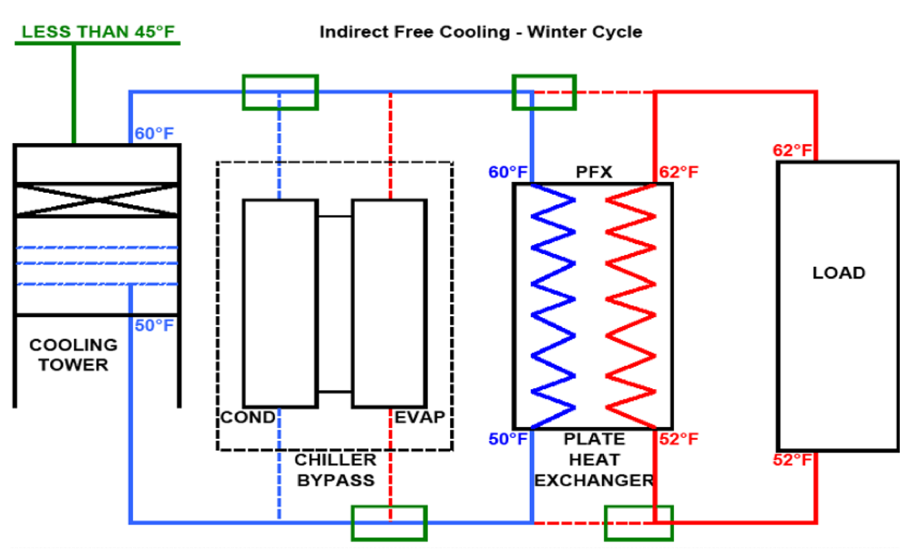

ASHRAE Standard 90.1 requires water-side economizers on almost all chiller installations in North America to reduce the high cost of running refrigerant compressors when making chilled water for commercial buildings. The water-side economizer cools or partially cools the chilled water loop with alternate sources to reduce electric consumption and save energy and money. The economizer takes the heat from the building chilled water loop to earth contact groundwater or to the air though an evaporative cooling tower.

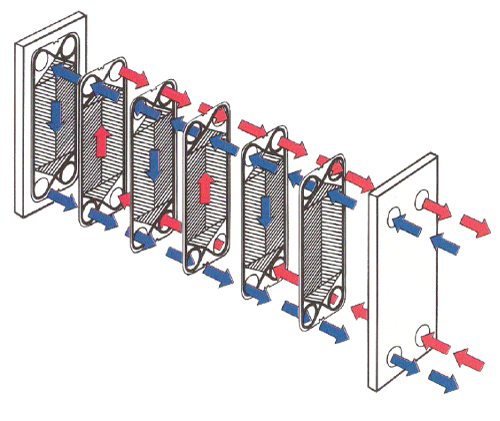

The WesPlate plate and frame heat exchanger is the perfect water-side economizer. It consists of specially corrugated metal plates that maximize heat transfer. Gaskets are fixed between the plates to contain and separate two fluids. These fluids flow alternately between every other plate, counterflowing to produce the greatest rate of heat transfer and provide the closest temperature approach to the incoming cooling tower or ground water. The special surface of the heat transfer plates provides a highly turbulent flow that scrubs the plates clean to reduce fouling and creates the highest rates of heat transfer possible.

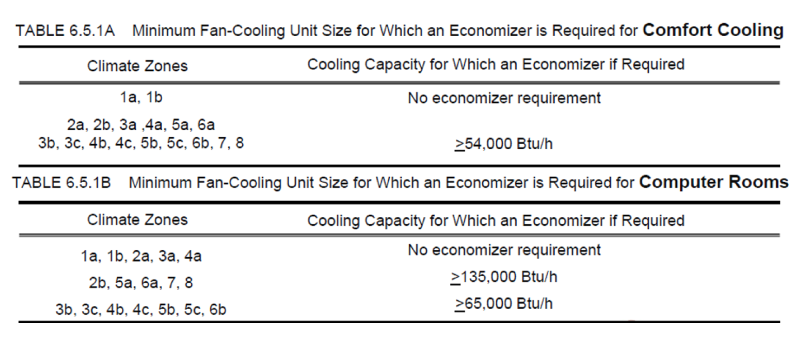

ASHRAE Standards are the specifications for engineers designing HVAC systems in North America. For ASHRAE 90.1 Energy Standard, the following requirement has been added:

6.5.1 Economizers. Each cooling system that has a fan shall include either an air or water economizer meeting the requirements of Sections 6.5.1.1 through 6.5.1.4

ASHRAE 90.1

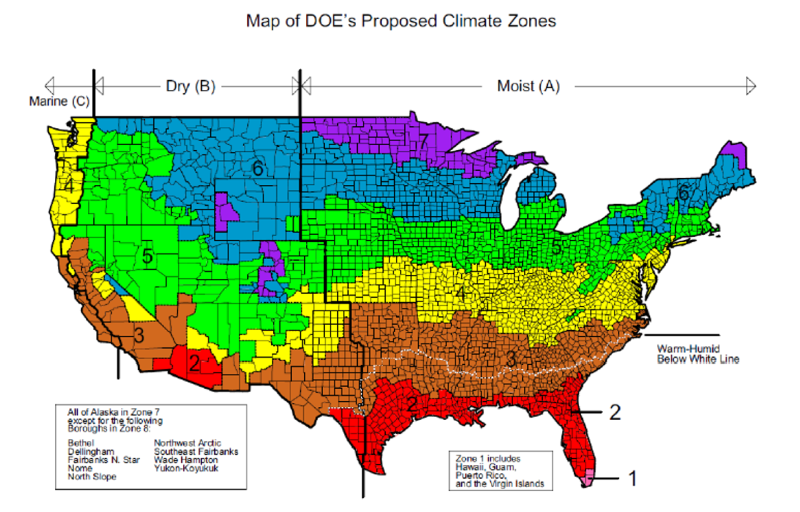

Engineers are required to add water-side economizing plate heat exchangers to almost all of their building designs. Because the efficiency of water-side economizers is limited by climate, ASHRAE has broken the US up in to climate zones.

How does it work? When a building requires about 500 tons or more for cooling purposes you go from an air-cooled refrigerant condenser in the air conditioner to a water-cooled condenser in the chiller. With water-cooled, there is typically a cooling tower or ground contact heat sink to move the heat from the building to the outside. A plate heat exchanger water-side economizer can be added to do some or all of the heat removal required by the building.

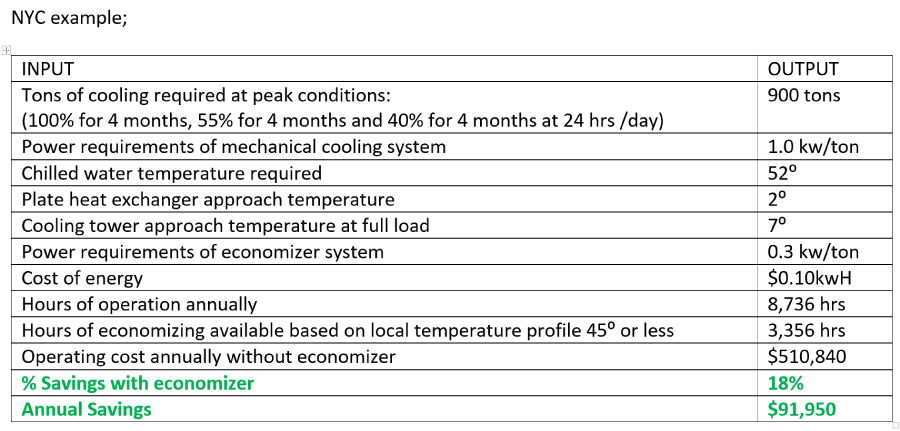

Economics. The savings of using a water-side economizer vary based on climate conditions at the location and how much chilled water is needed year-round. Installations with data centers require year-round cooling. An older mechanical/compressor system may operate as high as 1 kw/ton of refrigeration produced, while a system with a water-side economizer installed may operate as low as 0.3 kw/ton. So the savings can be calculated by taking the difference in operating cost between the full mechanical system and the costs when the water-side economizer is operating.

Example: NYC. A water-side economizer using a cooling tower typically works best when the temperature outside is down to 45⁰. So to calculate the savings of a system we must get a temperature profile of the region to see how often the water-side economizer will be running.

Seeing Green: The only way to guarantee savings and performance is to use AHRI Standard 400 certified plate heat exchangers like the WesPlate from Wessels Company. Wessels heat exchangers go through rigorous testing to be certified. ASHRAE 90.1 requires heat exchangers be AHRI certified and listed at www.ahridirectory.org.

For more information, check out https://www.westank.com/heat-exchangers/